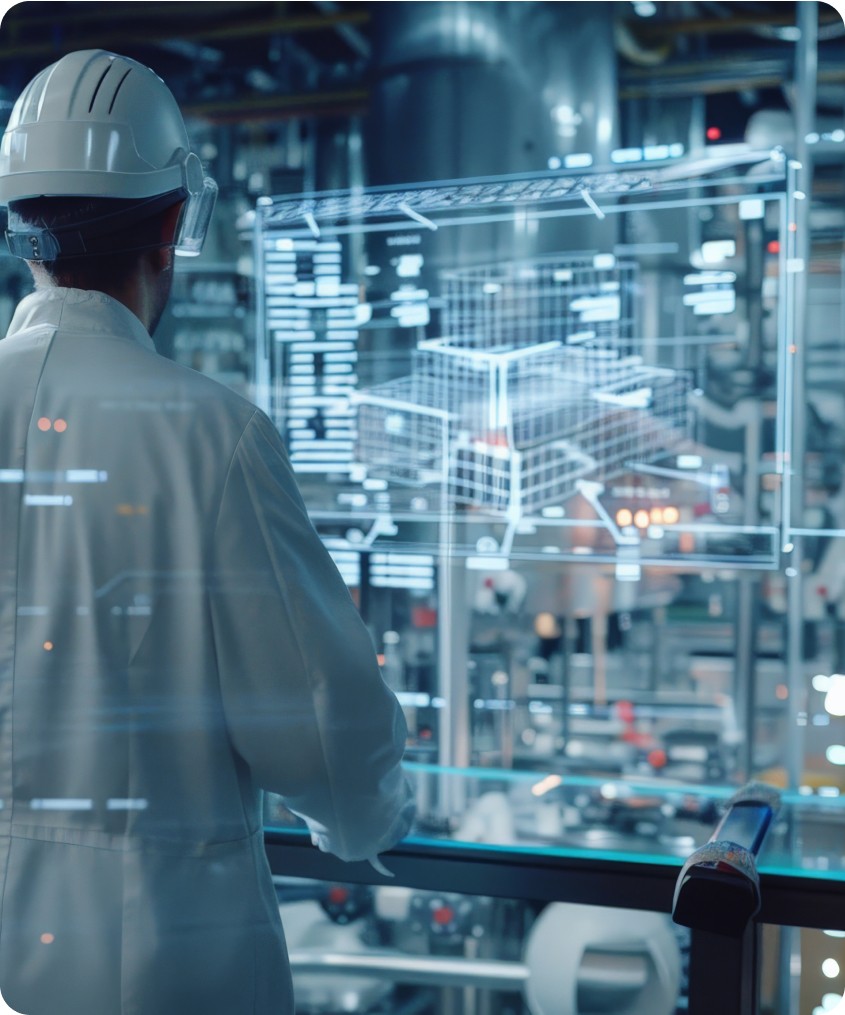

Digital Twins

AI-Driven Process Optimization

Enhancing performance using real-time data insights.

Predictive Maintenance

Identifying potential failures before they happen.

Operational Efficiency Modeling

Simulating real-world conditions to improve workflows.

Our smart factory solutions and Industry 4.0 implementation services help manufacturers modernize workflows, reduce waste, and leverage real-time data for continuous improvement. From connected machine controls to automated analytics, we engineer systems that work smarter — not harder.

Computer Vision for Quality Control

Automated Defect

Detection

Identifying flaws in real-time to reduce production waste.

Real-Time Quality

Analysis

Using AI for precision-based monitoring during manufacturing processes.

Vision-Based Sorting &

Classification

Ensuring high accuracy in product differentiation and grading.

Overall Equipment Effectiveness (OEE)

We help manufacturers maximize operational performance by applying AI to monitor and enhance equipment effectiveness. Our OEE-focused solutions include:

AI-Powered Production Monitoring

Identifying inefficiencies in real-time to reduce waste and increase throughput.

Root Cause Analysis

Leveraging AI-driven insights to minimize unplanned downtime and optimize processes.

Automated OEE Dashboards

Real-time tracking and visualization of key performance indicators across equipment and lines.

AI-Powered Predictive Maintenance

Failure Prediction Models

Using machine learning to anticipate equipment failures before they occur.

Vibration & Acoustic Analysis

AI-driven analysis of sensor data to detect early signs of mechanical issues.

Remote Equipment Monitoring

IoT-enabled sensors for real-time condition tracking and proactive maintenance.

Copyright Sruhad Technologies. All Rights Reserved.

Copyright Sruhad Technologies. All Rights Reserved.